Dial In – Gloss Black

Nate Hamilton & Enjuku team ready FDNJ!

Everytime we go out to any motorsport event its always impressive to see the behind the scenes. How much work it actually takes to run a program and to get a vehicle dialed in for competition is beyond impressive. More then that it is something that as an enthusiast you loose thought of because you’re only able to see the final show.

Watching the Enjuku Racing team is certainly no exception. So first lets give you a glimpse into what that actually looks like. On first sight you can literally feel the energy and intensity as everyone is working hard on the car in the final moments before the practice session starts. Right before the start of practice, walking into the Enjuku tent, the cars are clean, already race ready, setup with fresh tires and all fueled up. Hamilton is suited and moments away from jumping into the car to start the long process off tweaking the cars.

Over the next 5 hours all of the FD drivers would get maybe 10-12 runs give or take. At first, after runs the cars would end up back in the pits having changes made. Changing out gear sets, swapping tires, adjusting suspension, adjusting tire pressures and occasionally taking a quick break to hydrate up and have a quick conversation with team members and spotters about the strategy of how to attack that given track.

To be honest, its incredible to watch how dialed Nate and the Enjuku Racing crew are able to become in just a short amount of time. But by the end of the day on Thursday, the car looked ready, Nate had great lines and was looking aggressive and confident.

Friday’s qualifying proved to be no different. Nate’s First qualifying run was an 87, which would be his highest run. That score was solid enough to place him 13th and positioned to square off against Pat Goodin today in the top 32! We wish Nate and all of the Enjuku Racing team the best of luck. Make sure to tune in today on Youtube (NETWORK A account) or Formula Drift Live Page to watch Hamilton take on Goodin at 1:30pm EST!

[Not a valid template]Travis Reeder wins 1st place at FD Atlanta!

**** GUEST BLOG – BY TRAVIS REEDER****

This is a special recap for us. Not just because, as you will read, Travis Reeder took home a victory at Formula Drift Atlanta in the Pro 2 series. It’s special because that win comes at the start of a great relationship between Konig and Travis Reeder.

Travis is brand new to the Konig team! Reeder, hails from Vancouver, WA where he was the 2016 Evergreen Drift Pro-am Champion. That victory was what earned Travis his Formula Drift Pro 2 license. We came across Travis through a good friend of ours; Caleb Quanbeck. Caleb is also a friend of Travis and at Formula Drift Orlando Travis was having an issue with his other brand wheels breaking. Caleb stepped in and let Travis barrow his Konig Hypergrams to finish out the event. That finish resulted in a second place, podium finish. Having a podium finish at any point in the season or your career is amazing. Doing it in your first event EVER as a professional is unimaginable!

That night we received an email from Caleb and a message from Travis on Instagram. He was in need of some wheels and after only a few minutes we knew Travis was that hardcore, drift-loving enthusiast that was putting everything he had into his program. That’s the exact type of person we love to support, and we did. We reached out to Travis and with little time before the next Formula Drift event, we shipped some Konig Ultraforms in Gold right to Road Atlanta awaiting his arrival!

Keep in mind that Formula Drift Atlanta would be Travis’s second event as a professional Formula Drift Driver (the first event he placed 2nd in). Just like something written for a movie, Travis took first place in Atlanta and is currently the Formula Drift Pro 2 series points leader!

Check out what travis had to say about his experience…

Our weekend started off like any other event weekend. The team unloaded the car, tools and spare parts into the pit and got everything organized. I went through my normal routine of checking over fluids and nuts and bolts on the car. After orlando i knew the car was going to need an alignment due to the aggressive nature of the track, so we threw the strings on the car and got all our alignment setting dialed in. We were feeling good as well as optimistic going into Thursday’s practice and later qualifying sessions.

Coming into practice the car was feeling super solid so all i had to do was learn the track and find my line for qualifying. With this being my first time driving Road Atlanta i quickly realized that the track was extremely fast and super difficult to put the car into the zones needed for a solid scoring run. After a few sets of tires and a whole lot of fun jamming with the other guys in the field, i felt like i had a pretty good handle on the car and track layout.

The qualifying session snuck up pretty quick after practice but i was anxious to really stretch the car’s legs and throw down some solid runs. On my first qualifying run i had a solid entry and kept the car pretty far into the first outer zone on the rumble strips. Once in started making my way through the key hole i noticed i came off the first outer zone too quickly and struggled to get super deep into the second outer zone, which is a large chunk of points for the run. I was then able to dive into the inner clip with angle and power through the rest of the course. On my second qualifying run i came up the hill into the key hole with too much speed and ended up making a large mistake and almost spinning the car so i decided to shut the run down after that. Luckily my first run landed me in the 11th spot with a 71 so we were in the big show.

Fridays practice started late in the evening. I made a few conservative runs while noticing a vibration and what seemed to be a loss of power in the car. With only a short 45 minute session my team had to act fast to diagnose our issue. After a quick look over we noticed we had a burnt plug wire and had been running on 7 cylinders the past couple days. It didn’t take long however to source a new wire and get the car back to 100%, thanks Gale Hohnadell! We moved into top 16 intros and were feeling awesome and ready for some good battles.

My first battle in the top 16 was against Andy Hately. He qualified higher in the 6th position so he would lead first. I chased him down the hill after jumping the tree, knowing his car was pretty quick. I initiated right with him but ended up going a little wide around the first clip. Once transitioned i was able to make up ground up the hill and close the door entering the key hole, then proceeded to keep decent proximity throughout the rest of the course with minimal mistakes. On my lead run i was able to pull a gap of a couple car lengths while keeping the car on a good qualifying line with good angle. We were given the win and advanced into the top 8.

Entering the top 8, i was paired up against Hooman Rahimi. I qualified higher so i was set to lead first. I put down a pretty solid lead run with minimal mistakes and was able to pull a few car lengths in the process. On my chase run i initiated as close as i could to Hooman and was able to keep and maintain pretty tight proximity through the key hole and most of the course. It was enough to get the job done and i was awarded the win and advanced into the final 4.

The final 4 battle was set to put me up against Randall Waters. Randall’s car was extremely fast all night so i knew i really had to be aggressive and apply as much pressure as i could as i was going to be in the chase position for run 1. Unfortunately in my chase run i made a large amount of mistakes and in one judges eyes scored an incomplete due to mis-shifting and straightening the car out while exiting the key hole. During my lead run, Waters got a little too aggressive and made contact with my door on entry, which forced him to straighten and drive off track. This made a very difficult decision for the judges and by a stroke of luck i ended up advancing into the final battle.

Unfortunately the final battle against Matt Vankirk was un eventful after Matt broke off the start line. I was really looking forward to competing against Matt considering we had quite a bit of seat time together last year during pro am up at Evergreen Drift. Under the circumstances all i had to do was complete my by run and was crowned winner at rd 2 Road Atlanta!

I’d like to thank Konig Wheels for their massive support of my program this year as well as all my crew, family and other sponsors. See everyone in Seattle!

**********************

We WELCOME TRAVIS REEDER TO THE TEAM! If you don’t follow him, now is the time to go check him out! This is one talented guy and we have a feeling there is a lot more in Travis’s future!

Travis Reeder is a Konig Sponsored driver that runs 17×9 front/18×9 rear et23mm Konig Ultraform wheels in Gold. The Ultraform are flow formed and perfect for the harsh environment that drifting provides. Make sure to follow Travis Reeder and Instagram and Facebook:

TRAVIS REEDER – FACEBOOK: https://www.facebook.com/travisreederracing/

TRAVIS REEDER – INSTAGRAM: https://www.instagram.com/travisreeder/

Speedway Academy’s “5-Day Track Build Challenge” Episodes 1-4

So if you have been under a rock lately you might have missed that Speed Academy is underway on a 5 Day Track Car Challenge Build. Just incase the build title wasn’t clear enough, they are basically building a track car in 5 days a documenting it for the world to see. The guys of Speed Academy are super informative and bring a hell of a resume. Again, incase you were under that rock we keep speaking of, Peter Tarach was the former editor of Modified Magazine and David Pratte has been writing for books such as Modified, Performance Auto Sound Magazine (PASMAG) and many other slick projects. Their content is amazing and fun to watch.

Here is the added bonus! They linked up with the master of everything that is Honda, Brian Gillespie, to pull off the build! Brian is the owner of Hasport Performance, Vtec Academy (Cough…cough…check them out here…VTEC ACADEMY. They will be running Konig Hypergram’s in Race Bronze. Ok so now you know its a Honda! Ok now you know its a Honda and what wheels they are going to run BUT…it’s a 5 day swap! We are super excited to have been able to help bring you this series.

Want want to help you get up to speed so below we are helping you binge watch! Check it out here, you’re welcome 🙂

The K-Swap Civic Is So Beat Up! – 5 Day Track Build Challenge – EP02

K20 Swap Made Easy With The Right Parts – 5 Day Track Build Challenge – EP03

More Parts Installed on the K20 Swap Civic – 5 Day Track Build Challenge – EP04

Robbins & Koruworks run Konig in 17!

Konig is excited to announce their partnership with Koruworks and their driver this year, Alec Robbins. Their widebody 350z is incredible and Koruworks is a first class operation, make sure to check them out (info below)!

Alec got his start in motorsports at a young age. Growing up, he spent much of his time with his father at car shows and other various motorsports events. Having been riding snowmobiles, dirt bikes and four wheelers ever since he could reach the handlebars, Alec has always been at home with anything on wheels. Having an itch for adrenaline, he has been into extreme sports as well and started racing motocross at the age of 14 where his hunger for competition and all out racing on the edge began. Alec’s love for cars began to develop shortly after getting his drivers license. His parents gave him his first vehicle; a 1986 Nissan d21 truck. The truck was a hand-me-down and was purchased by his dad in 1987. Throughout highschool Alec made it his own by lowering and adding a few small custom touches to the truck.

After high school, Alec continued his education and passion for cars and got a degree in automotive service at a local technical college. It was in College that he discovered drifting and had to give it a try. A Chevy v8 was sourced from a car behind a neighbors shed was dropped in the D21 truck, along with a welded diff and some minor suspension modifications. Alec attended some of his first drift events in 2013 and shortly after he started pushing harder and winning most of the local drift events he was attending. All the while the truck was getting upgraded just as fast as Alec’s skills progressed. Eventually a 400hp LS2 and t56 transmission found its way into his dads old truck.

In 2016 it was time to take the next step and Alec went out to drive in the Midwest Drift Union Pro-am series. Having only driven a few tracks locally, the higher level of driving and new tracks were the main reasons for making the jump to pro-am. Alec quickly made heads turn at round 1 by being the first and only truck in the pro-am series, and kept all eyes on him by qualifying 3rd and taking home a 4th place finish at out of a 40+ driver field! Alec continued the high qualifying and was able to finish on the podium at the remaining 3 rounds making him the MDU season champion AND rookie of the year.

In 2017, Alec will take the next step up the ladder and make his debut as a Pro-2 rookie. Alec was able to join forces with Koruworks LLC and will be debuting their all new 350z. Sporting Konig Hypergrams, a Chevy crate LS3, Gforce transmission, Quick change rear end, Wisefab arms and knuckles with Fortune auto suspension, and a little extra help from Nitrous Express; It is the recipe Alec needed to progress his driving to its highest level.

Back home Alec currently works for Metro Transit, as a mechanic on locomotives and passenger rail cars. He is newly married to his wife Chelsea Robbins and has two children, Elliana and Ryder Robbins. Alec spends most of his off time with his family or working on his cars in the shop. They also enjoy going to local drift events, car cruises, and bracket drag races with their gear head in laws. To say the least, family and racing are what drives Alec to be the man he is today.

[Not a valid template]Alec Robbins and the Koruworks team run Konig Hypergrams in 18×9.5 et 25 all the way around in Race Bronze. Here the team’s contact info, make sure to follow them!

Koruworks: koruworks.com/

Instagram: https://www.instagram.com/koruworks/

Alex Robbins Racing Instagram: https://www.instagram.com/alecrobbinsracing/

Knapik heads to Formula Drift pro 2 round 2

Knapik Heads to Formula Drift Pro 2 Round 2 in Atlanta!

Adam Knapik is one of those enthusiasts that loves cars and drifting so much that he will take an endless amount of a abuse just to have the opportunity to spend his day on track. Unfortunately that is exactly what has been happening to Adam and his team, abuse!

Preparing for Round 1 of Formula Drift Pro 2 in Orlando, with only days left before loading the car on the trailer for the cross country journey, Adam’s engine developed a rod knock. To blame was a faulty oil check valve…as disappointed as they were, the clock had run out and the game was over. While making the trip to Orlando wasn’t in the cards the team knew they needed to keep on pushing. Round 2 in Atlanta was only 2 weeks late and they still had to get a new engine in the car, tune it and make the cross country trip to Georgia. After a few days of work Knapik and the team had their backup LS2 engine swapped in, tuned and ready to flex in Atlanta this coming weekend at Road Atlanta.

We’ve been proud to be associated with Adam and his program for a few years now. ** Check out this video of Adam from a couple of years ago:**

He made his way through some road racing and time attack events but drifting seems to be where his heart is. Competing previously in Top Drift, a win there paved the way for his Formula D pro 2 license.

We look forward to see what Knapik and his team will do in Atlanta and are proud to have the opportunity to support an incredible driver and real enthusiast! Good Luck Adam…

[Not a valid template]Adam Knapik is a Konig Sponsored Formula Drift Pro 2 Driver that runs the Flow Formed Konig Rennform in 18×9 et23 all the way around on his Nissan 240sx S14.

If you want to keep tabs on Adam here is where you can follow him along:

Website: http://knapikracing.com/

Instagram: https://www.instagram.com/knapikracing/

Facebook: https://www.facebook.com/KnapikRacing

Kelsey Rowlings talks FD Orlando

Kelsey Rowlings took a few minutes to run through her experience at Formula Drift Orlando. It’s not everyday that you can climb in the mind of a professional driver and really know what they were thinking and feeling. Kelsey takes over the rest of this blog to do just that! Check it out below!

Round One of Formula Drift’s Pro 2 at Orlando Speedworld was a solid start for my team and I. We had a few hiccups starting in Thursday’s practice where we had to deal with a low oil pressure issue that we thought we had fixed during testing. The issue popped up again during Thursday practice when the oil pressure would drop below 35psi ever so briefly, and trigger a “safety mode” we set on our Haltech ECU. That safety would set the rev limiter to 5k RPMS to save any damage to the engine without cutting all the power in case it were to happen at a bad part of the track. It is a great safety feature, but drifting the OSW bank when the power is limited is still extremely sketchy!

Besides the low oil pressure issue, we noticed that the amount of blow-by coming from our driver-side head was not normal. We were getting too much blow-by from one side and not the other. Worried we had an internal issue, we compression tested the engine. To our relief, the numbers were perfect, but we did notice another issue while looking over our data logs. The engine ran so cool that the oil temperature was not rising above 200 degrees. We also discovered that the breather on the passenger side head that led to our catch can had a PCV type valve in it. We drilled out the valve to allow more breathability, and we covered a portion of our oil cooler with tape to make the cooling less efficient. With these few small changes, we fixed the problem and were back in business!

Once we got the car settled, I started feeling more prepared and ready for qualifying. When we went out for our qualifying run, I realized the sun was right in my line of vision for the entry making it extremely difficult to see and judge the distance before entry. Without a tinted visor or sunglasses, I knew I had to just go for it. I committed to my entry and threw the car hard. Once I was entering I realized I was just the slightest bit late, setting me up for a really high line… too high. I tap the wall with a decent amount of force, but I correct and floor the throttle. I tap again, lighter this time and again stay in the gas. I steer my car down off the bank and past the first inner clip almost perfectly. I transition slightly cautiously through the infield, knowing I had a close call on the bank and that I needed to clean up my act towards the end. I pass the second inner clip with good proximity and push out into the final outer zone. I make my way around the apron and finish the run that would be my high score, a 73, putting me in 10th for qualifying.

My qualifying position meant I was against the number 7 qualifier from Australia, Josh Robinson, in his imported Holden Ute. I was excited to drift with a car that we don’t have in the US. During top 16 practice, my spotter informed me that Josh was having trouble during the transition through the infield, and spun almost every time due to some issues they were having with the car. Josh was also kind enough to let me know before the battle of his struggles with the car so I wouldn’t be surprised on track.

Knowing Josh’s Ute was much slower than my Coyote powered rocket ship, and knowing he was having issues, I decided I was going to give him some room for the entry so I wouldn’t get stuck behind him during initiation. Unfortunately, Once I started to take of from the line, I realized I may have been in fourth gear instead of second, the gear I normally start in. I quickly took the car out of gear and slam it back into second to be sure and take off as fast as I can behind Josh. I wanted to give him a little room… but it turned into playing a game of catch up!

I round the bank with my eyes set on the Ute. I gain on him quickly as we head down the bank towards the inner clip. In my head, I’m wondering if he is going to make the transition successfully. I navigate through the smoke and once I see his car settled the other direction, I hammer down. I bump the second inner clip as I get closer and closer, positioning myself on his door for the last few seconds of the run.

Knowing my follow run wasn’t ideal, I wanted to put down the best possible lead run. That is where I got in my head. I floored it and clutch-kicked into the bank on a really high line. I tap the wall lightly followed by a larger tap and a big correction. I stay in the gas and throw more angle to keep the front end away from the wall. I over-corrected, bringing my car down the bank a bit too early, putting two tires off course to the inside coming down the bank. I correct and make it past the first clip, transition to the second inner clip where I stay in it for a solid finish.

Unfortunately, I beat myself as soon as I tapped the wall, forcing me to over-correct and go tires off. I wanted to put down an amazing run but just went a bit too hard! Although we were knocked out in the top 16, I’m happy with my driving overall, and I look forward to Round two at Road Atlanta, where I plan to go 100%… instead of 110%… 🙂

-Kelsey Rowlings

[Not a valid template]Kelsey Rowlings teams up with Konig – Formula Drift Pro 2

We are extremely excited to announce that Kelsey Rowlings has partnered up with Konig for the 2017 Formula Drift Pro 2 season. Kelsey is super down to earth, a real car enthusiast and an incredibly talented professional drifter.

Kelsey started to get into drifting about 10 years ago around the time she was graduating from high school. Like many people the excitement of the sport of drifting sucked her in and paved the way for an exciting professional drifting career. She began competing in Pro-Am competitions and with several years of hard work she placed 4th overall in the Streetwise Drift ProAm series in 2014, and 2nd overall in the 2014 Three Palms Drift ProAm series. That is where Kelsey earned her Formula Drift Pro 2 license for the 2015 season.

In 2015, Kelsey become only the second woman in Formula Drift history to qualify for tandem competition. Kelsey continued to work hard on her skills and her program in 2016 by competing in the Pro 2 series as well as a multitude of drift events, exhibitions and demos. We’re very proud to be a small part of Kelsey’s program for 2017.

Make sure to check back here for more information on Kelsey and her season updates! You can also follow her:

KELSEY ROWLINGS – INSTAGRAM

KELSEY ROWLINGS – FACEBOOK

Wheels Running:

Konig Hypergrams 18×8.5 Front / 18×9.5 Rear

The Konig Hypergram is a Flow Formed wheel that is lightweight and strong. The Hypergram was a new release in 2016 and has been a popular choice in motorsports, especially the drifting community.

What Is Flow Forming Technology

Flow forming technology is one of the most advanced manufacturing technologies to enter the wheel industry. Flow Forming Technology involves the application of pressure to the inner barrel of the wheel, while spinning and after it has been casted. This process stretches and compresses the aluminum, which increases tensile strength. In this respect the process shares similar properties to those found in the forging process. The final product is lighter, stronger, has increased elongation, and a much greater shock resistance as well as the ability to increase load capacity over a traditional cast wheel (of the same design).

1: THE FLOW-FORMED PROCESS APPLIES PRESSURE ON THE INNER WHEEL WHILE SPINNING AFTER CASTING

2: THIS PROCESS STRETCHES AND COMPRESSES THE ALUMINUM, WHICH INCREASES TENSILE STRENGTH

3: THE FINAL PRODUCT IS LIGHTER, STRONGER, HAS INCREASED ELONGATION, AND GREATER SHOCK RESISTANCE

Interested in seeing more Flow Formed Wheels? Here is a link to all of the Konig Flow Formed Wheel offerings –> FLOW FORMED WHEELS

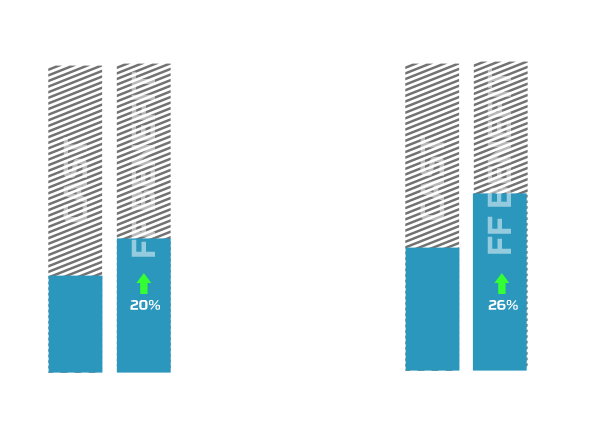

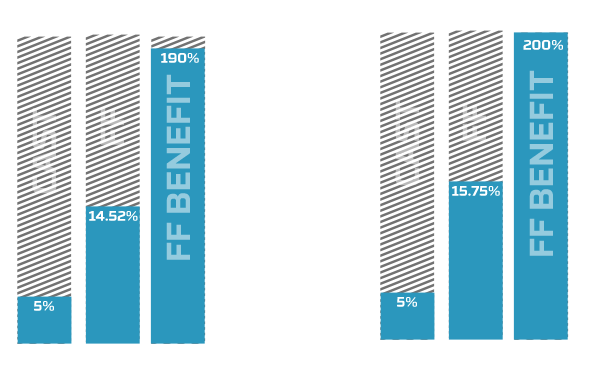

Flow Forming Technology has a great number of benefits. Konig has been producing Flow Formed wheels since 2010 and is always improving on the process and efficiency to improve the end product. Below are some visual charts for you to see the drastic benefits as it relates to elongation and tensile strength vs a regular cast wheel. The numbers used are approximate and only for general comparison. These are based off of wheels similar in styling, size, width and other specification. One wheel was a conventional cast constructed wheel and the other is developed using Flow Forming Technology.

TENSILE STRENGTH

ELONGATION

ELONGATION

What is Elongation?

Elongation is essentially the amount of flex that an object can have before it would reach a breaking point. So you might be asking why would it be more beneficial that a Flow Formed Wheel can flex more before it could ever reach that point? Well, its important when we talk about wheels that everyone should acknowledge that wheels are metal not magic.

While that may be a humorous line its incredibly true. We only build wheels to the highest quality. Konig places every wheel design through a very strict testing standard and build each design to load ratings which are in excess of what is needed for that design’s target vehicles. However, any wheel, regardless of whether it’s an aftermarket wheel or the original factory wheel, has a breaking point. Severe impact and the stress impacts over time can push the metal to a breaking point.

So let’s get back to the benefit that we started talking about earlier. If a wheel safely has the ability to flex more before ever reaching a breaking point that will increase reliability and longevity of a wheel. This is a benefit to racers on the track as well as the road hazards of everyday use on the street. .

If you have any questions, feel free to contact us!

New For 2017!

With new Konig wheel additions for 2017 to both the Konig Flow Formed & Main Line wheel collections, Konig continually develops product which includes both forward styling and performance for the street or track.

The Konig 2017 line-up features the all new Konig Ultraform & Impression wheels which were inspired by our history in motorsport and produced with the most state of the art technology. The end result is a product that is strong & lightweight!

The Ultraform is a lightweight, 7-spoke design that has been developed for strength on the track while offering a modern and aggressive look when rolling around town. The Ultraform’s design lends to efficient brake cooling as well as exceptional brake caliper clearance. With widths up to 10.5″ wide, toughening up the stance on many rear wheel drive vehicles is an easy task. Constructed with Flow Forming Technology, the Ultraform is light, strong and contains more elongation and shock resistance than a traditional cast design. The Ultraform is offered in 17×8″, 17×9″, 18×8, 18×8.5″, 18×9″, 18×9.5″, 18×10.5″, 19×8.5″, 19×9″, 19×9.5″, 19×10.5″ and finished in Gloss Graphite.

The Impression is a unique, split 10-spoke, face-forward design that will have heads turning for another look. Finished in Gloss Black with Machined Face, the Impression is available in 16×7.5”, 17×7.5”, and 18×8” sizes. The Impression has fitment for many popular passenger vehicles and is ready to make your vehicle stand out from the crowd!

Check the out below for the full product specs & sizing on these NEW wheels from Konig!

New Wheel Additions

Konig Ultraform

Sizing & Specs

The Ultraform is a lightweight, 7-spoke design that has been developed for strength on the track while offering a modern and aggressive look when rolling around town. The Ultraform’s design lends to efficient brake cooling as well as exceptional brake caliper clearance. With widths up to 10.5″ wide, toughening up the stance on many rear wheel drive vehicles is an easy task. Constructed with Flow Forming Technology, the Ultraform is light, strong and contains more elongation and shock resistance than a traditional cast design. The Ultraform is offered in 17×8″, 17×9″, 18×8, 18×8.5″, 18×9″, 18×9.5″, 18×10.5″, 19×8.5″, 19×9″, 19×9.5″, 19×10.5″ and finished in Gloss Graphite.

Konig Impression

Impression Sizing & Specs

The Impression is a unique, split 10-spoke, face-forward design that will have heads turning for another look. Finished in Gloss Black with Machined Face, the Impression is available in 16×7.5”, 17×7.5”, and 18×8” sizes. The Impression has fitment for many popular passenger vehicles and is ready to make your vehicle stand out from the crowd!